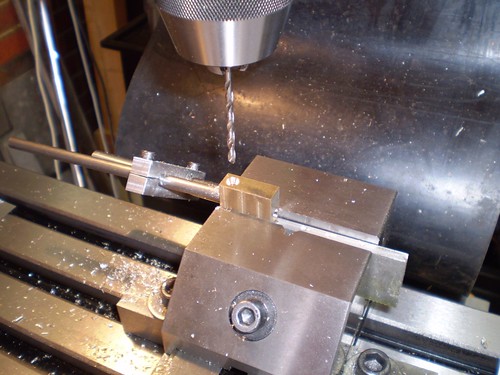

The steam outlet is a fitting at the top of the boiler that provides a threaded attachment for the main steam line. It is made of brass; of which we start with a small block on the mill drilling the passages out.

Once that is done we cut out a small bit of waste to make our lives easier when we mount in the lathe.

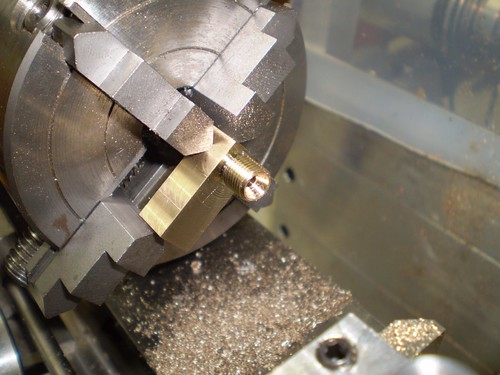

Using a spring loaded wobbler (actually it is the Taig live center, but it does double duty here) center the part so that the first boss can be turned.

Turning complete now we have to thread 5/16-32 ME - a common size for commercially available nuts and tails.

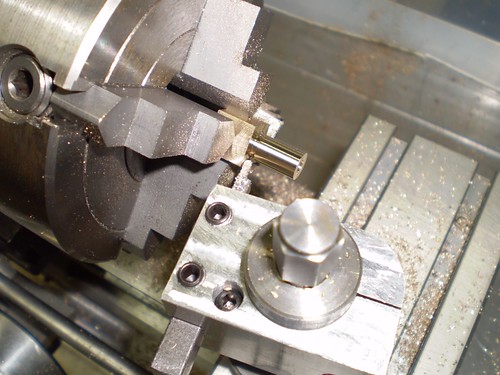

Threading complete. I also turned a small semicircular groove where the boss meets the square section and chamfered the end.

Here is a shot taken whilst turning the groove on the other boss. This boss is at 90 degrees to the other one and is smaller - in this case 0.250".

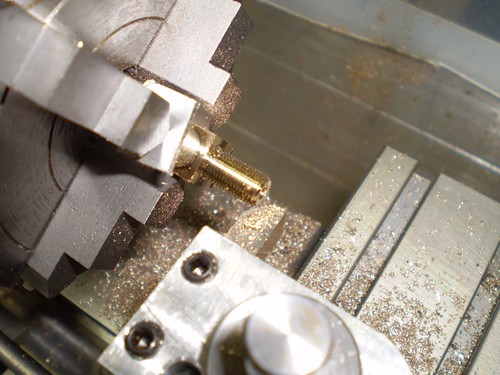

This boss gets threaded 1/4-40ME and chamfered as well. Note the piece of soft aluminium protective packing between the chuck jaw and the part.

The finished article.

No comments:

Post a Comment