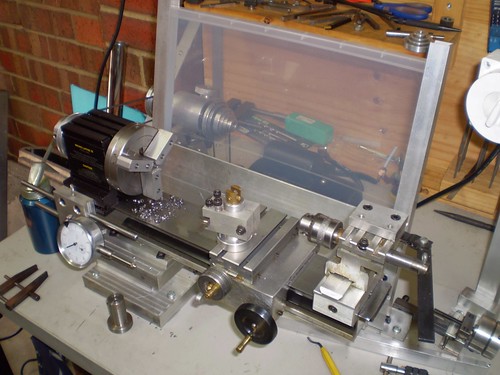

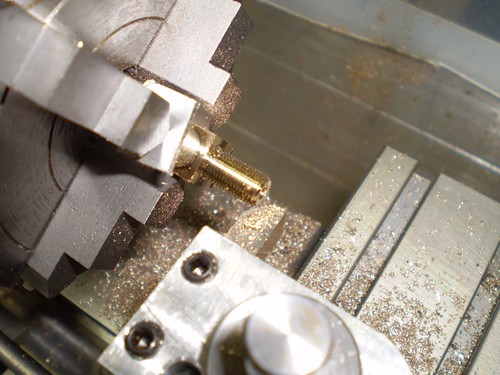

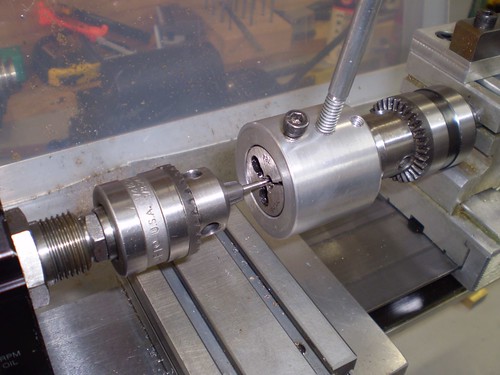

As can be seen in this shot, my Taig lathe has a dial gauge mounted under the headstock that I use to measure carriage travel. The mounting block also includes provision for a stop rod. A web surfer asked me recently to post some more detailed photos of the mounting.

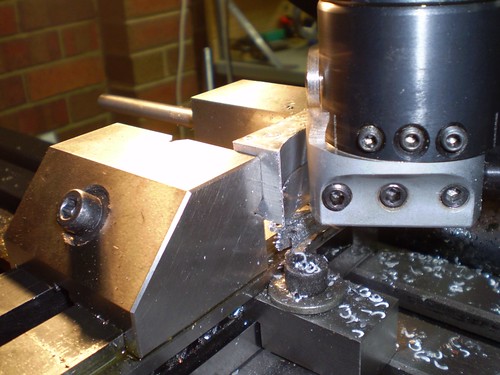

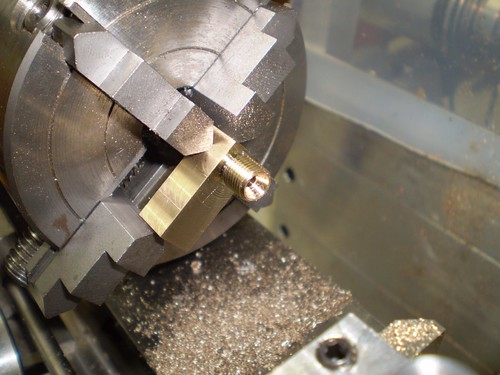

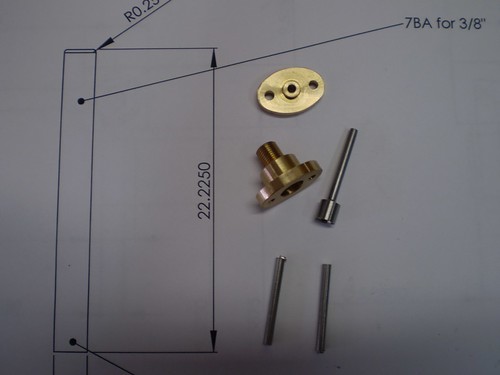

The block itself is L-shaped. The two cap screws pass through and into the T-slots in the headstock. The thumbscrew was the one that came with the lathe. It holds the stop rod (a piece of 0.250 silver steel/drill rod) in place with the aid of a brass pad.

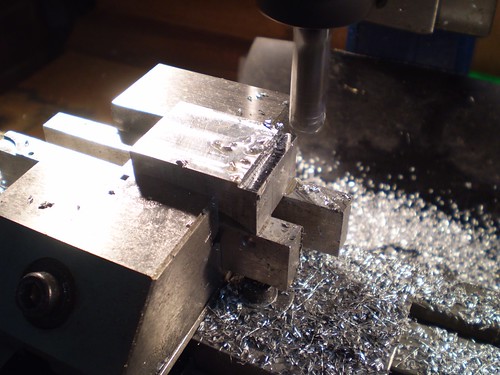

The dial gauge is mounted on a rod which passes through the hole pictured below. A clamping mechanism is devised from a slot and another cap screw.

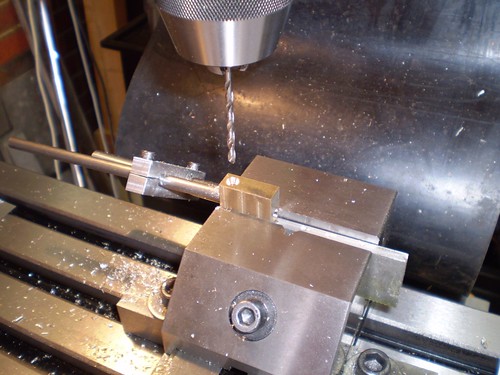

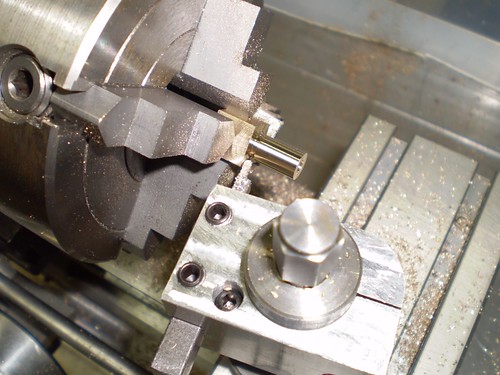

Here is the mount for the dial gauge. The rod is held on the block via a grub (set) screw, and the dial is mounted via another cap screw.