I got inspired and decided I would give my father a home made present this (last) year. So I decided to make my version of the Elmer's Wooden Beam Engine. The wood I used was Mountain Ash, which is an Australian hardwood. The finish is just a rub down of linseed oil.

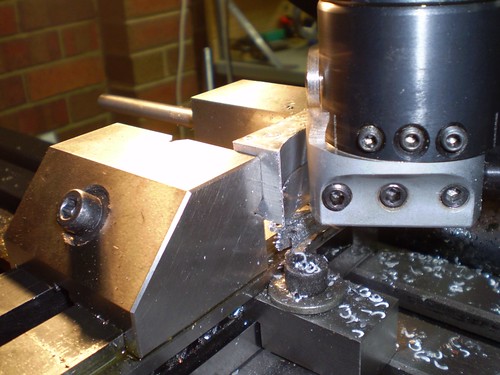

My version uses a flywheel made out of metal (aluminium actually). This was cut on the CNC mill. Here is a close-up of the crank shaft.

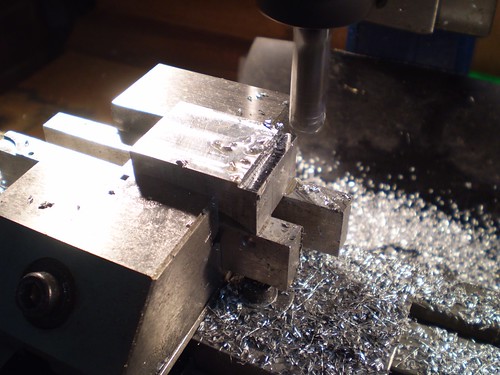

I also used a steel connecting rod. I used a ball end mill to give it a cruciform cross-section. Here is a longer shot - I pretended to be a blacksmith and forged the ends of the stay rods for a bit of whimsy.

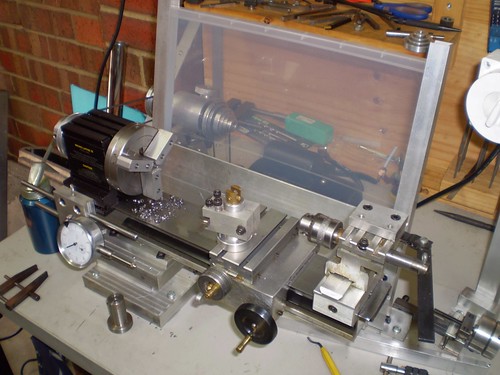

The cylinder was made from cast iron. The center piece was tuned on the lathe, and the top and bottom caps where done on the CNC mill.

Here is the other side. The valve housing was turned from mild steel on the lathe.

Here is a better shot of the valve gear.

Here is a shot of the cylinder end of the beam.

Video to follow...